Description

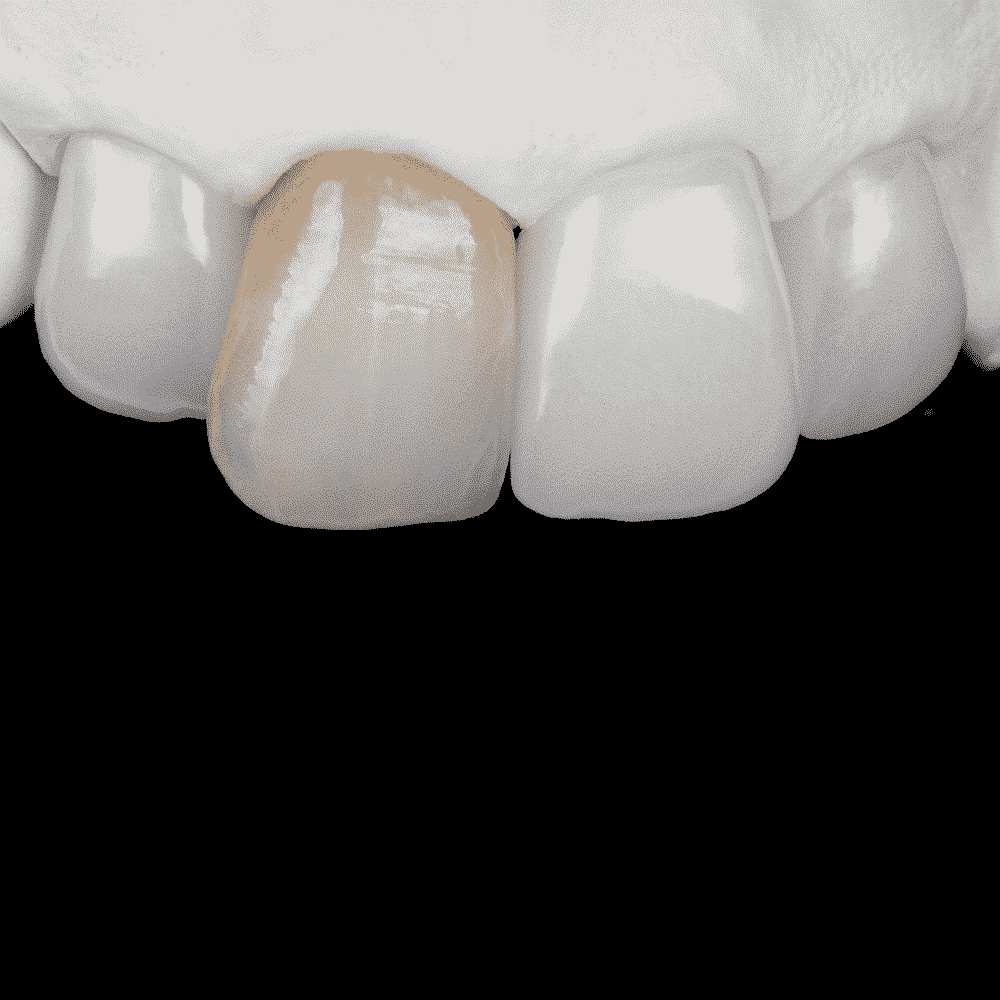

MiYo is a completely NEW and REVOLUTIONARY colouring/staining system for FULL CONTOUR zirconia or Lithium Disilcate restorations which gives unique depth, texture and vitality on very thin thicknesses (0.1 – 0.2mm). MiYO is the easy way to match shades and get the depth and translucency needed on monolithic or cutback crowns – all in one firing! In addition it’s a:

- Correction Material: Quick and easy way to change a shade, raise or lower the brightness of crowns (whilst adding translucency) or add contacts to reduce remakes!

- Alternative to costly hand-layered ceramics: It’s an efficient way to create highly characterised restorations that rival aesthetics typically only seen with hand-layered restorations in unprecedented thicknesses of 0.1mm-0.2mm

The following 2 Kits are available:

- The MiYO Aesthetic System for tooth restorations

- The MiYO Pink Aesthetic Gingiva System for Tissue

Key Advantages at a glance:

- Different types of self-glazing colours with varying levels of translucency, each uniquely formulated to replicate nature’s subtleties, such as incisal translucency, mamelons, crack lines, halos, and gingival tissue.

- Create depth, vitality, and texture found in natural enamel and tissue, in unprecedented thicknesses of 0.1mm-0.2mm, requiring no cut back or modification to CAD designs, making them ideal for full contour restorations.

- Control value, hue and chroma; hit your target shades easily

- Float colour on colour. See colour, form and subtle nuances before fired; no surprises

- Create colour and structure as thin as 0.1mm – 0.2mm

- Match Vita shades quickly and easily in one firing. Ability to add fluorescence, translucency and opacity; get depth and contrast

- Natural vital looking depth created for tooth and tissue. 3D effects without reducing monolithic crowns

- No colour changes with firing. What you see is what you get.

- Unique viscosity structure pastes; change/add surface texture. Less shrinkage and increased colour stability; build and keep the surface texture

- Firing is done in the glaze cycle; save time and money with reduced processing time

Rapid application process; produce more units daily.

Reviews

There are no reviews yet.